Now for a word on dowel sticks. Usually, I use a 1/4" wooden craft type dowel stick. Mine are about 36" long. However, some people like small thin steel rods which give some weight for holding the fabric and dowel in place while pleating. Some people like a cafe curtain rod which opens or closes as much as needed for garments, either adult or child. The size of the dowel should be compatible with the fabric type used.

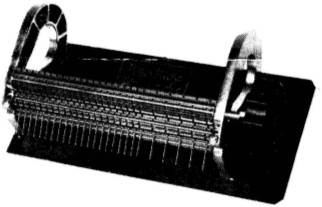

When using double needles (whole space and half space), the machine will be harder to turn. This is especially true for BROADCLOTH, which is harder to turn, even using single space needles. This is normal. Turn slowly and carefully. Trim ALL SELVAGES. We recommend using as few of the needles as possible with broadcloth. Half-spaces with broadcloth increase the possiblity of breaking needles.

Please ask us any questions and we will let you know what we can do to help you.